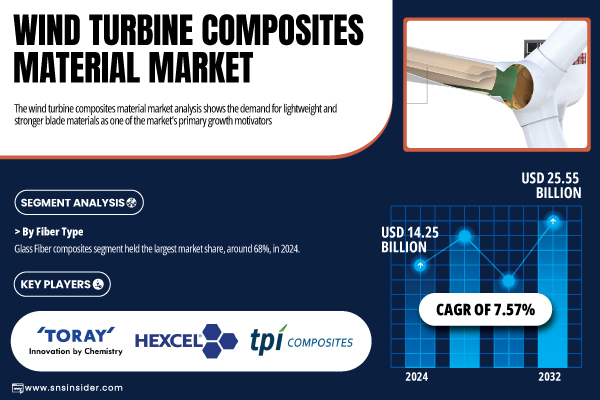

Austin, Aug. 04, 2025 (GLOBE NEWSWIRE) -- The global Wind Turbine Composite Materials Market was valued at USD 14.25 billion in 2024 and is projected to reach USD 25.55 billion by 2032, expanding at a CAGR of 7.57% from 2025 to 2032.

Trend towards sustainable energy generation and the development of high-capacity onshore as well as offshore wind turbines will continue to drive market growth and further promote the use of advanced composite materials having improved strength-to-weight ratios, corrosion resistance, and long service life in extreme weather and environmental conditions.

Composite materials (e.g., glass and carbon fibers and epoxy resins) are widely employed in wind turbine components' manufacturing, which include rotors, nacelles, and hubs. The increasing demand for longer, more aerodynamic blades in both offshore and onshore applications is forcing manufacturers to switch to carbon fiber and hybrid composites to decrease weight, improve energy capture, and retain their structural integrity.

Download PDF Sample of Wind Turbine Composites Material Market @ https://www.snsinsider.com/sample-request/7736

The U.S. wind turbine composites material market size was USD 2.84 billion in 2024 and is expected to reach USD 5.44 billion by 2032 and grow at a CAGR of 8.44% over the forecast period of 2025-2032. This was attributed to well-established wind energy infrastructure, strong support from the government for renewable energy, and the presence of major composite manufacturers and wind turbine OEMs. Wind power in recent years, the country has been witnessing a sizzling growth in wind power capacity, which has largely been concentrated in the Midwest and Texas, driven by supportive policies, including the Production Tax Credit (PTC) and clean-energy mandates.

Key Players:

- TPI Composites

- Hexcel Corporation

- Teijin Limited

- Toray Industries

- LM Wind Power

- Vestas Wind Systems

- Siemens Gamesa Renewable Energy

- Gurit Holding

- Suzlon Energy

- Mitsubishi Chemical

Wind Turbine Composites Material Market Report Scope:

| Report Attributes | Details |

| Market Size in 2024 | USD 14.25 Billion |

| Market Size by 2032 | USD 25.55 Billion |

| CAGR | CAGR of 7.57% From 2025 to 2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | • By Resin Type (Epoxy, Polyester, Vinyl Ester) • By Fiber Type (Glass Fiber, Carbon Fiber) • By Application (Blades, Nacelles, Others) |

If You Need Any Customization on Wind Turbine Composites Material Market Report, Inquire Now @ https://www.snsinsider.com/enquiry/7736

By Fiber Type

Glass fiber segment accounted for 68% of the market value share in 2024 on account of its low cost, superior mechanical strength, and established usage in wind blade production. It's a global leader, particularly for onshore installations, in big, utility-scale wind projects around the world. At the same time, the use of carbon fibre proves increasingly attractive for offshore applications due to its light weight, high stiffness, in combination with fatigue resistance, which is particularly important for any long-span blade operating in a turbulent wind environment.

By Resin Type

Epoxy segment was the leading segment with a market share of 52% in 2024. Wind turbine composite production prefers epoxy resins due to their excellent mechanical properties, adhesion and thermal properties. These are the ones most commonly combined with glass and carbon fibers in the production of blade. Other resin systems (for example, polyester, vinyl ester) are also employed, especially in cost sensitive cases, and smaller wind turbines.

By Application

Blade held a market share of 75% in 2024 leading the global blade market. The blades of wind turbine are the largest and most important components of the structure of a wind turbine, in which composite materials are used. Add More Length, More Power Doubling the blade length to increase the capacity of the turbine to generate electricity would require cutting-edge composite materials to maintain strength and durability while reducing weight. Nacelles and hubs are also very significant parts when it comes to increasing turbine sizes, which requires materials with high mechanical properties as well as environmental resistance.

Regional Analysis

Asia-Pacific was the leading region in the global wind turbine composites with the highest value share of 38% in 2024. Much of this is due to swift wind energy expansion in China and India, solid government backing for renewables, particularly clean energy and huge commitments to both onshore and offshore wind projects. China, in particular, is the global leader in wind power capacity and wind turbine manufacturing, and this is a contributor to the demand for composites. Europe made a close second, as countries such as Germany, the UK, and Denmark invested heavily in offshore wind farms.

Recent Developments

- In March 2025, LM Wind Power (a GE Renewable Energy business) presented its newest offshore blade at 115 meters long and being produced from carbon-glass hybrid composites to achieve higher energy output with less material levy.

- In December 2024, TPI Composites, Inc., in collaboration with Siemens Gamesa, announced our plans to increase wind blade manufacturing capacity in India and Turkey to support the increasing wind demand of the Asia-Pacific and European offshore wind industry.

Buy Full Research Report on Wind Turbine Composites Material Market 2025-2032 @ https://www.snsinsider.com/checkout/7736

Unique USPs of the Wind Turbine Composite Materials Market

- Blade Length Optimization – Composite materials enable the design of longer, more aerodynamic blades to maximize power output.

- Weight-to-Strength Efficiency – High strength-to-weight ratio of composites enhances turbine stability and reduces operational strain.

- Corrosion Resistance – Excellent resistance to environmental degradation makes composites ideal for offshore turbines.

- Design Flexibility – Composite materials support complex geometries for advanced blade engineering and aerodynamics.

- Lifecycle Durability – Superior fatigue resistance improves turbine lifespan and reduces maintenance costs.

- Sustainable Manufacturing – Increasing use of recyclable and bio-based composite materials aligns with global ESG goals.

- Localized Production Hubs – Growing regional manufacturing clusters reduce supply chain risks and support job creation in clean energy.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.