Anchorage Alaska, Aug. 04, 2025 (GLOBE NEWSWIRE) -- Nova Minerals Limited (“Nova” or the “Company”) (NASDAQ: NVA) (ASX: NVA) (FRA: QM3) ) is pleased to announce results from the ongoing RPM gold feasibility metallurgical test work program, which is showing exceptional recoveries in our opinion, with potential further opportunities to optimize for even higher recoveries.

Highlights

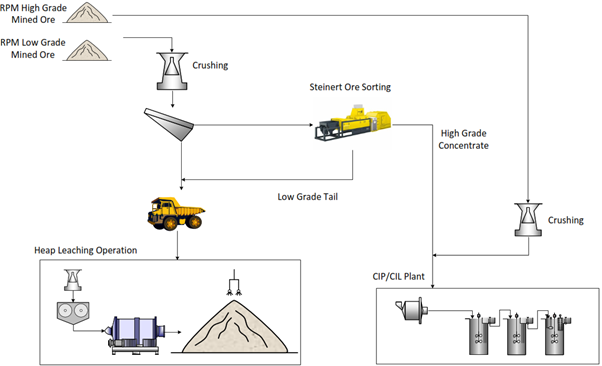

- RPM conceptual flowsheet outlines clear path to high gold recoveries (Figure 6).

- High-grade ore over 2 g/t Au fed directly into the carbon in pulp (CIP)/carbon in leach (CIL) circuit to optimize gold recovery.

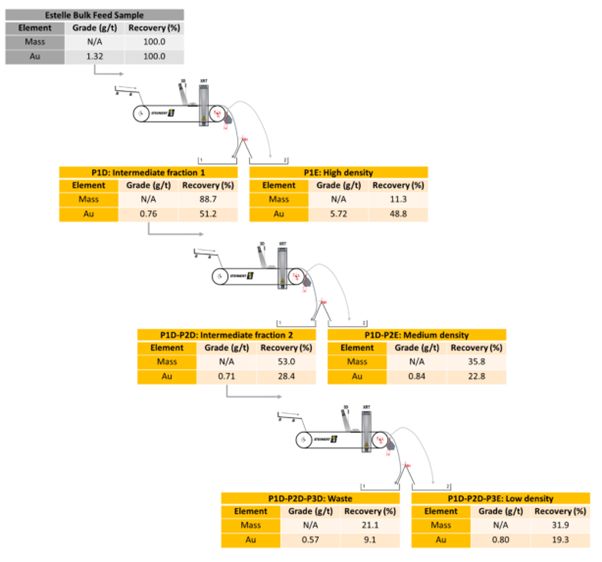

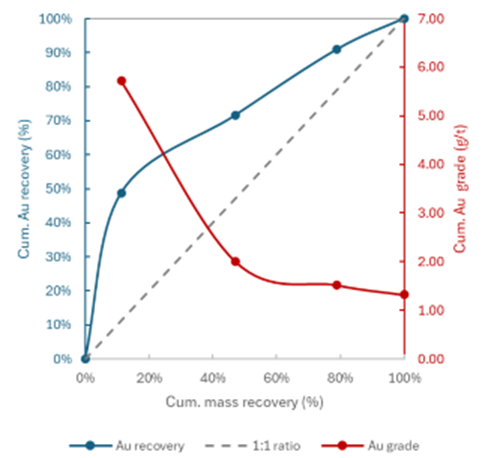

- Ore below 2 g/t Au will be processed through the ore sorter, where a 1,000 kg bulk test with Steinert Mining upgraded 1.32 g/t Au material to 5.72 g/t Au — an increase of 4.33 times in a single pass (Figures 1, 2 and 3).

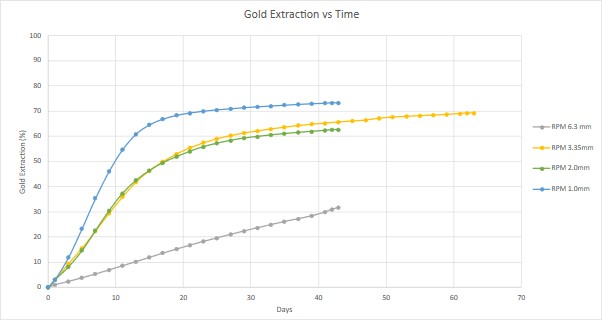

- Lower-grade ore rejected by the sorter will undergo heap leaching, with column tests showing potential gold recoveries as high as 68.7% (Figure 4 and 5 and Table 1).

- Advanced sorting technology expect to increase the volume of high-grade feed to processing circuits, optimize resources and maximize orebody value.

- Ongoing CIP/CIL test work for the Pre-Feasibility Study (PFS) aims to advance this part of the flowsheet.

- High pressure grinding rolls (HPGR) crushing test work is in progress to further optimize the flowsheet and provide power cost efficiencies in the PFS.

Nova CEO, Mr Christopher Gerteisen commented: “We are extremely pleased with the results emerging from our ongoing metallurgical test work program at the RPM Deposit, which we believe continues to demonstrate the exceptional quality and scalability of the Estelle Project.

The ability to extract up to 68.7% gold recovery from lower-grade material through heap leaching, combined with a 4.33 times upgrade using ore sorting technology, is a significant technical breakthrough, in our opinion. These results underscore the economic potential through innovative processing methods as we continue to refine our development pathway.

This multi-pronged flowsheet approach — incorporating ore sorting, heap leaching, and CIP/CIL processing has the potential to be a best-in-class strategy for maximum gold recovery, efficient capital deployment, and lower processing costs. We believe RPM has the hallmarks of a low-cost, high-margin gold producer.

With CIP/CIL test work well underway and further optimization on ore sorting and HPGR crushing still to come, we believe the upside could be significant. These preliminary results strengthen our belief that Estelle is a potential world-class, long-life gold district capable of delivering sustained value to shareholders.

Nova remains focused on delivering the next major North American gold mine, and these latest results from RPM bring us another step closer to achieving that vision.”

Ore Sorting Test Work Results

Particle density X-Ray Transmission (XRT) ore sorting is a proven technology which has been successfully implemented as part of the pre-treatment concentration process in many mines around the world. X-rays are used to examine the density of the rock being sorted in order to separate a target mineral, ore or element from waste prior to the haulage, crushing and processing mining stages. By rejecting a considerable proportion of the lower grade rock before processing through the mill, the mill feed grade is effectively increased and energy requirements and tailings generation are reduced, resulting in a more environmentally friendly mining operation with improved overall mine efficiencies and economic benefits.

The process starts with raw ore being scanned with X-rays and data collected from the detector. With the help of big data and intelligent algorithms, the ore and waste rock is separately identified and a high-pressure blower sprays the waste rock away to realize efficient automatic intelligent sorting. To see a short video of how ore sorting works please go to https://novaminerals.com.au/strategy-and-studies/#oresorting

Figure 1. Steinert ore sorter

Nova and METS Engineering (METS) partnered with Steinert Mining (Steinert) to evaluate RPM orebody amenability to sensor-based ore sorting.

Test work at Steinert was conducted in 2 stages with sighter test work undertaken followed by a large 1,000 kg bulk test. The result from the bulk test work program demonstrated the Estelle RPM ore is amenable to ore sort upgrading with a XRT and 3D-laser combination algorithm. Figure 2 illustrates the three stage test work process undertaken by Steinert to evaluate the amenability of the ore. Figure 3 presents the cumulative recovery, mass pull and grades obtained from the test work.

Figure 2. Steinert Illustration of the three-stage XRT and 3D-laser separation process, reporting the mass yields, Au recoveries and Au grades for the Estelle RPM gold bulk sample

The results presented in Figure 2 demonstrated that a high density fraction can be recovered through ore sorting in which 48.8% Au is recovered in a mass yield of 11.3% in the first pass. This generated a concentrate of 5.72 g/t Au from a 1.32 g/t feed – a 4.33 times upgrade in the first pass through the ore sorter. Steinert strongly recommends Nova Minerals implement sensor sorting into the Estelle RPM process, to obtain a relatively high grade concentrate in a low mass yield. The implementation of the ore sorting technology has the potential to be further optimized.

Figure 3. Cumulative gold recovery (%), mass pull (%) and grade (g/t) for the Estelle RPM gold bulk sample

Heap Leaching Metallurgical Test Work Results

Heap leaching is a low capital and operating cost alternative to conventional mill processing techniques for gold recovery from lower grade ore sources. It is a well-proven and cost-effective approach used by the majors including Barrick Gold, Newmont, Kinross Gold’s Alaskan Fort Knox and Eldorado Gold’s Kışladağ mine to name a few.

Heap leaching can potentially recover the gold from 100’s of millions of tons of lower grade material, and the reject material from the ore sorters, which otherwise would be regarded as waste. This has the potential to significantly increase the gold production from the project.

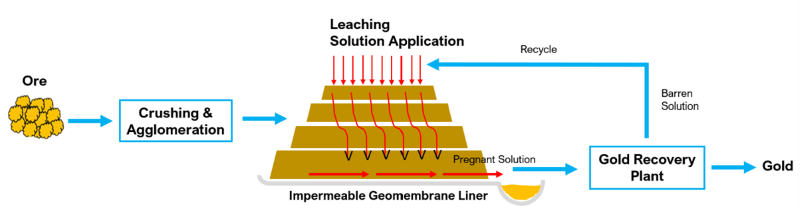

Figure 4 below shows how a typical heap leach process works with ore put through an optional pre-application phase before being stacked on an impermeable heap pad. The pad is then irrigated with a leaching agent for an extended period of time which chemically reacts with the ore to dissolve the gold into a solution as it percolates through the heap. The impregnated solution is then collected at the bottom of the heap and the gold is recovered though a gold processing plant, with the barren solution recycled to start the process again.

Figure 4. A typical heap leach process

Heap leaching has a number of benefits including:

- Recovers low grade gold from ore that was previously sent to waste, resulting in higher potential gold production.

- Lower capital cost relative to other methods of gold recovery, as with only higher-grade ore now going through the plant, a smaller plant is required.

- Simple process with lower operating costs than conventional processing techniques (lower energy consumption, less equipment configuration).

- Can move a project to cashflow at a quicker pace and generate the capital required to finance the more expensive processing facilities.

- Suitable for all climates eg: The Fort Knox gold mine in Alaska uses heap leaches to extract gold.

Nova engaged METS Engineering to undertake test work to evaluate the amenability of RPM to heap leaching. METS undertook a comprehensive prefeasibility heap leaching test work program on low grade RPM ore. The program consisted of crush size sensitivity testing, agglomeration and percolation testing and culminated in four heap leach column tests. The material used in the column test was crushed using High Pressure Grinding Rolls (HPGR).

Table 1 presents the results of the column leach test work which shows that at an achievable crush size of 3.35 mm after 59 days of leaching 68.7% gold extraction can be achieved from RPM low grade ore. Cyanide consumption ranged from 0.61 to 0. 92 kg per ton of ore. Lime consumption ranged from 0.081 to 0.139 kg per ton of ore. Both reagent consumptions are reasonable for heap leaching.

Table1. Heap leach column test work results

| Test ID | Crush Size | Days under leach | Au % | NaCN (%) | NaCN kg/t | Lime kg/t |

| MN3544 | 3.35 mm | 59 | 68.7 | 0.05 | 0.92 | 0.139 |

| MN3545 | 2.00 mm | 43 | 62.6 | 0.05 | 0.77 | 0.095 |

| MN3546 | 1.00 mm | 43 | 73.4 | 0.05 | 0.77 | 0.109 |

Figure 5 illustrates the gold leaching kinetics for each of crush size obtained from the column test work. The low grade ore was still leaching when the columns were terminated and during heap leach operations in the field a much longer leach cycle could be utilized.

Figure 5. RPM column leach test work results

RPM Conceptual Flowsheet

Based on the positive test results Nova is pleased to present a high level conceptual flowsheet for RPM processing that is being further developed with test work and engineering underway.

This flowsheet demonstrates the capability to fully utilize the RPM resource combining Steinert Ore Sorting Technology, Heap Leaching and CIP/CIL. The high-level conceptual flowsheet is presented in Figure 6.

The implementation of ore sorting technology is designed to allow for the upgrading of low-grade RPM mined ore to high grade concentrate appropriate to feed a CIP/CIL plant. The rejects from the ore sorter will then be heap leached in a suitably sized operation to maximize the recoverable gold from the RPM deposit. Additional engineering and economic trade-off studies will be conducted to determine the optimum size of the heap leach operation and CIP/CIL plant to achieve the best economic outcomes for the Estelle project.

Figure 6. High level conceptual flowsheet for Estelle RPM ore

Qualified Persons

The information contained in this report, relating to metallurgical results, is based on, and fairly and accurately represent the information and supporting documentation prepared by Mr Damian Connelly. Mr Connelly is a full-time employee of METS Engineering who are a Contractor to Nova Minerals Limited, and a Fellow of The Australasian Institute of Mining and Metallurgy. Mr Connelly has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration, and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Exploration Targets, Mineral Resources and Ore Reserves and as Qualified Person as defined in Regulation S-K 1300 under the Securities Act of 1933, as amended (S-K 1300). Mr Connelly consents to the inclusion in the report of the matters based on the results in the form and context in which they appear.

About Nova Minerals Limited

Nova Minerals Limited is a Gold, Antimony and Critical Minerals exploration and development company focused on advancing the Estelle Project, comprised of 514 km2 of State of Alaska mining claims, which contains multiple mining complexes across a 35 km long mineralized corridor of over 20 advanced Gold and Antimony prospects, including two already defined multi-million ounce resources, and several drill ready Antimony prospects with massive outcropping stibnite vein systems observed at surface. The 85% owned project is located 150 km northwest of Anchorage, Alaska, USA, in the prolific Tintina Gold Belt, a province which hosts a >220 million ounce (Moz) documented gold endowment and some of the world's largest gold mines and discoveries including, Nova Gold and Paulson Advisors Donlin Creek Gold Project and Kinross Gold Corporation's Fort Knox Gold Mine. The belt also hosts significant Antimony deposits and was a historical North American Antimony producer.

Further discussion and analysis of the Estelle Project is available through the interactive Vrify 3D animations, presentations, and videos, all available on the Company’s website. www.novaminerals.com.au

Forward Looking Statements

This press release contains “forward-looking statements” that are subject to substantial risks and uncertainties. All statements, other than statements of historical fact, contained in this press release are forward-looking statements. Forward-looking statements contained in this press release may be identified by the use of words such as “anticipate,” “believe,” “contemplate,” “could,” “estimate,” “expect,” “intend,” “seek,” “may,” “might,” “plan,” “potential,” “predict,” “project,” “target,” “aim,” “should,” "will” “would,” or the negative of these words or other similar expressions, although not all forward-looking statements contain these words. Forward-looking statements are based on Nova Minerals Limited’s current expectations and are subject to inherent uncertainties, risks and assumptions that are difficult to predict. Further, certain forward-looking statements are based on assumptions management believes to be reasonable at the time such statements are made, including but not limited to, continued exploration activities, Gold and other metal prices, the estimation of initial and sustaining capital requirements, the estimation of labor costs, the estimation of mineral reserves and resources, assumptions with respect to currency fluctuations, the timing and amount of future exploration and development expenditures, receipt of required regulatory approvals, the availability of necessary financing for the Project, the availability of funding sources, the availability of collaborative relationships, permitting and such other assumptions and factors as set out herein. Apparent inconsistencies in the figures shown in the MRE are due to rounding.

Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of the Company to be materially different from those expressed or implied by such forward-looking information, including but not limited to: risks related to changes in Gold prices; sources and cost of power and water for the Project; the estimation of initial capital requirements; the lack of historical operations; the estimation of labor costs; general global markets and economic conditions; risks associated with exploration of mineral deposits; the estimation of initial targeted mineral resource tonnage and grade for the Project; risks associated with uninsurable risks arising during the course of exploration; risks associated with currency fluctuations; environmental risks; competition faced in securing experienced personnel; access to adequate infrastructure to support exploration activities; risks associated with changes in the mining regulatory regime governing the Company and the Project; completion of the environmental assessment process; risks related to regulatory and permitting delays; risks related to potential conflicts of interest; the reliance on key personnel; financing, capitalization and liquidity risks including the risk that the financing necessary to fund continued exploration and development.

These and other risks and uncertainties are described more fully in the section titled “Risk Factors” in the final prospectus related to the public offering filed with the Securities and Exchange Commission. Forward-looking statements contained in this announcement are made as of this date, and Nova Minerals Limited undertakes no duty to update such information except as required under applicable law.

For Additional Information Please Contact

Craig Bentley

Director of Finance & Compliance & Investor Relations

M: +61 414 714 196