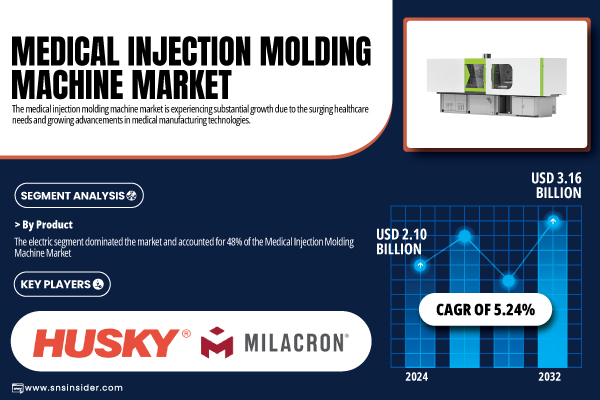

Austin, July 17, 2025 (GLOBE NEWSWIRE) -- The medical injection molding machine market size was valued at USD 2.10 billion in 2024 and is expected to reach USD 3.16 billion by 2032, growing at a CAGR of 5.24% over the forecast period of 2025–2032. The medical injection molding machine market is benefiting from the trend towards higher molding precision and efficiency. With the modern rehabilitation sector moving towards the use of minimally invasive devices and single-use instruments, manufacturers depend on the availability of advanced machines to ensure high-quality and cleanliness standards. The growing emphasis on sustainability and energy conservation also drives the demand for next-generation molding systems.

The U.S. medical injection molding machine market is expected to grow from USD 0.28 billion in 2024 to USD 0.41 billion by 2032, at a CAGR of 4.80%. Key drivers increase in minimally invasive surgical procedures, the demand for patient-specific medical parts, and regulations focused on expediting the traceability of materials and facilities' cleanroom conformance.

Download PDF Sample of Medical Injection Molding Machine Market @ https://www.snsinsider.com/sample-request/7429

Key Players:

- Sumitomo (SHI) Demag Plastics Machinery GmbH

- Husky Injection Molding Systems Ltd

- Milacron MSA

- Engel Machinery India Pvt. Ltd.

- Arburg GmbH + Co KG

- The Japan Steel Works, Ltd.

- KraussMaffei Group

- Toshiba Machine Co., Ltd.

- Wittmann Battenfeld

- UBE Machinery

Medical Injection Molding Machine Market Report Scope:

| Report Attributes | Details |

| Market Size in 2024 | USD 2.10 Billion |

| Market Size by 2032 | USD 3.16 Billion |

| CAGR | CAGR of 5.24% From 2025 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2025-2032 |

| Historical Data | 2021-2023 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Drivers | • Rising Demand for Medical Devices Driven by Chronic Diseases and Aging Population Spurs Growth in Advanced Injection Molding Solutions. |

Electric Machines, Hot Runner Systems, and Plastic Materials Drive Medical Injection Molding Market Leadership in 2024

By Product

The electric segment dominated the medical injection molding machine market, capturing 48% of the overall market share in 2024. Their ability to produce micro parts with high accuracy, repeatability, and energy efficiency is critical, and it has resulted in this sector driving much of the growth in the industry. Electric injection molding machines use servo motors to control the injection speed, pressure, and position with much higher accuracy. Unlike hydraulic machines, they generate less noise and no hydraulic oil leakage, and they are also well-suited for cleanroom usage.

By System

The hot runner system segment held the largest share in the medical injection molding machine market in 2024, accounting for approximately 58%. It is now the most preferred system due to its efficiency in shortening cycle times for cost reduction and enhancing favourable aspects of clean production by eliminating leftover plastic waste, which is crucial for environmental sustainability. Hot runner systems maintain the plastic in a liquid state within heated channels, thus resulting in a more uniform component quality and fewer faults. It makes it suitable for high-volume, high-precision applications like syringe bodies, IV, and catheter connectors.

By Material

Plastics continued to dominate the medical injection molding machine market by material type in 2024, representing around 86% of the total market share. This phenomenon is a result of growing dependency on synthetic polymer-based products, such as in single-use and less-invasive medical devices. Plastics inherently provide very good functionality, like complex geometries, lightweight, and relatively cheap tooling. Additionally, numerous types of medical-grade plastics like PP, PC, PE, and so on, provide high biocompatibility, chemical resistance, and sterilization compatibility.

If You Need Any Customization on Medical Injection Molding Machine Market Report, Inquire Now @ https://www.snsinsider.com/enquiry/7429

Asia-Pacific Leads Growth in Medical Injection Molding Market, with North America Advancing in Precision and Automation

Asia Pacific holds a commanding position in the global medical injection molding machine market, capturing 38% of market share in 2024, and stands out as the fastest-growing region. The growth of pharmaceutical and device manufacturing hubs in China, India, Japan, and Southeast Asia is driving the region's significant market dominance. Especially for injection molded items such as syringes, diagnostic cartridges, and microfluidic chips, local medical device firms are swiftly ramping up production to meet domestic and international demand. The demand for electric and hybrid injection molding machines is also driven by the growing adoption of automation and energy-efficient manufacturing in the medical sector, supported by governments in the region.

North America holds a significant share in the medical injection molding machine market, driven by its mature healthcare infrastructure and demand for high-quality, precision-engineered medical devices. With the availability of automated systems and inline monitoring and traceability features, next-generation electric injection molding technology is principally adopted in the U.S. and Canada. Regulations affecting device sterilization, complicated design of implants, and innovations for single-use medical devices are driving OEMs to align with molding-machine manufacturers that help with cleanroom requirements and digital sensor integration.

Table of Contents – Major Key Points

1. Introduction

2. Executive Summary

3. Research Methodology

4. Market Dynamics Impact Analysis

5. Statistical Insights and Trends Reporting

6. Competitive Landscape

7. Medical Injection Molding Machine Market Segmentation, By Product

8. Medical Injection Molding Machine Market Segmentation, By System

9. Medical Injection Molding Machine Market Segmentation, By Material

10. Regional Analysis

11. Company Profiles

12. Use Cases and Best Practice

13. Conclusion

Buy Full Research Report on Medical Injection Molding Machine Market 2025-2032 @ https://www.snsinsider.com/checkout/7429

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.