Austin, July 09, 2025 (GLOBE NEWSWIRE) -- Metal Fabrication Equipment Market Size & Growth Analysis:

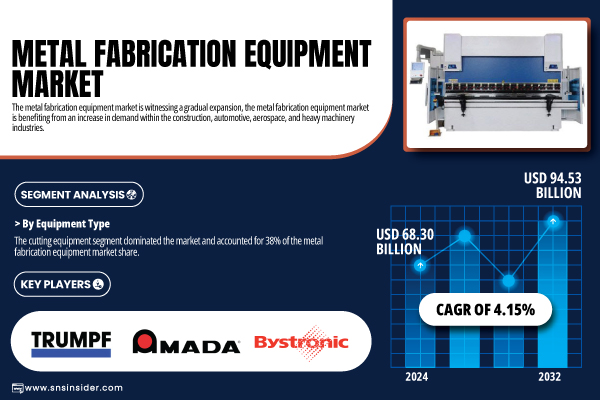

According to SNS Insider, the Metal Fabrication Equipment Market size was valued at USD 68.30 billion in 2024 and is expected to reach USD 94.53 billion by 2032, growing at a CAGR of 4.15% over the forecast period of 2025–2032. Strong demand from the automotive, aerospace & construction sectors is encouraging the digital & robotics integration in a wide range of operations to boost efficiency & reduce costs. Deployments of smart manufacturing, including IoT-driven predictive maintenance, laser cutting systems, and robotic welding arms, are lifting productivity and product quality. Investments are also being driven by sustainability efforts, energy-efficient equipment, waste‑recovery technologies, etc.

Get a Sample Report of Metal Fabrication Equipment Market@ https://www.snsinsider.com/sample-request/7506

The U.S. metal fabrication equipment market, valued at USD 12.13 billion in 2024, is projected to grow at a 4.57% CAGR, reaching USD 17.34 billion by 2032. Growth is driven by accelerating adoption of precision robotic systems in automotive and aerospace manufacturing, government incentives for reshoring, and rising demand for welded, laser-cut, and formed metal components.

Major Players Analysis Listed in this Report are:

- Trumpf Group (Germany)

- Amada Corporation (Japan)

- Bystronic Laser AG (Switzerland)

- Yamazaki Mazak Corporation (Japan)

- Sandvik AB (Sweden)

- DMG Mori (China)

- Okuma Corporation (Japan)

- Hypetherm Associates Inc (U.S.)

- Prima Industrie (Italy)

- BLM Group (Italy)

Metal Fabrication Equipment Market Report Scope

| Report Attributes | Details |

| Market Size in 2023 | US$ 68.30 billion |

| Market Size by 2032 | US$ 94.53 billion |

| CAGR | CAGR of 4.15% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Regional Analysis | North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Poland, Turkey, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (UAE, Saudi Arabia, Qatar, South Africa, Rest of Middle East & Africa), Latin America (Brazil, Argentina, Rest of Latin America) |

Cutting Equipment, Steel, and Automotive Lead Metal Fabrication Equipment Market Dominance in 2024

By Equipment Type

The cutting equipment segment dominates the metal fabrication equipment market, accounting for 38% of the total market share in 2024. Accelerating demand for high-precision cutting tools, including laser cutters, plasma cutting systems, water-jet cutting machines, is the key factor contributing to the industrial growth during the forecast time period. Advanced cutting technologies are used for precision in various industries such as automotive, aerospace, and shipbuilding, are are capital-intensive and used for better material usage. Automated and CNC-based cutting systems can aid in improving operational efficiency and can drive down the overall human error is likely to boost the segment growth.

By Material Type

Steel remains the leading material in the metal fabrication equipment market, holding a dominant 42% market share in 2024. Steel, with its rising demand across industries like construction, automotive, and energy, continues to be the most widely fabricated material. The best combination of strength, durability, low cost, and versatility serves as the structural framework in most buildings and is an excellent choice for various applications, including machinery parts. Rising emphasis on infrastructure creation and the manufacture of electric vehicles has further driven up the demand for steel fabrication solutions.

By End User

The automotive segment is the largest end-user of metal fabrication equipment, holding a significant 32% market share in 2024. The growing need for fabricated parts like chassis parts, body frames, exhaust systems, and engine mounts from the same sector is driving the adoption of equipment. The expanding electric vehicle (EV) market is another reason for the demand for lightweight yet strong components, where advanced fabrication technologies such as laser cutting and robotic welding come into play. Moreover, with the high volume of production, manufacturers are also investing in automation for the quality of the product.

For A Detailed Briefing Session with Our Team of Analysts, Connect with Us Now@ https://www.snsinsider.com/request-analyst/7506

Metal Fabrication Equipment Market Segmentation

By Equipment Type

- Cutting Equipment

- Laser Cutting Machine

- Plasma Cutting Machine

- Waterjet Cutting Machine

- Flame Cutting Machine

- Others (Bandsaws, etc.)

- Machining Equipment

- CNC Machine

- Lathe Machine

- Drilling Machine

- Welding Equipment

- Arc Welding Machine

- Resistance Welding Machine

- Laser Welding Machine

- Robotic Welding Equipment

- Bending & Forming Equipment

- Press Brakes

- Rolling Machine

- Stamping Machine

- Others (Strech Forming Equipment, etc.)

- Others (Shearing Equipment, etc.)

By Material Type

- Steel

- Aluminum

- Copper

- Others (Alloys, etc.)

By End User

- Automotive

- Aerospace & Defense

- Construction

- Electronics

- Energy

- Shipbuilding

- Others (Consumer Goods, etc.)

Asia-Pacific Dominates Metal Fabrication Equipment Market, While North America Emerges as Fastest-Growing Region.

Asia‑Pacific dominated the metal fabrication equipment market with a 38% share in 2024, led by China, India, and Japan. These have been driven primarily by an expanding automotive and construction sector, rapid industrialization, and low costs of labor. As the world’s manufacturing behemoth, China remains the largest buyer and producer of automation technologies, with its massive investments in advanced machinery showing no sign of abating. The “Make in India” drive has initiated extensive deployment of fabrication lines, robo‑welders, and laser‑cutters, thereby enhancing domestic capability and export competitiveness. Japan is still very much ahead in technology in precision forming and stamping systems, namely in the electronics, automotive, and aerospace industries.

North America is the fastest-growing region in the metal fabrication equipment market in 2024, due to continuous industrialization and technological advancements, along with increasing automotive and aerospace industries that fuel demand for metals. The U.S. dominates growth, with cloud-based companies and incumbents pouring money into automation and smart manufacturing. From aerospace to automotive, industries are deploying sophisticated CNC welding cells, robotic finishing systems, and additive‑metal hybrid machines. This trend is getting reinforced with government support for domestic manufacturing in terms of grants and tax incentives through initiatives like the CHIPS and Science Act. As noted, the domestic focus on precision in engineering and sustainability of processes is driving the adoption of energy-efficient equipment, closed-loop control systems, and predictive-maintenance solutions.

Buy a Single-User PDF of Metal Fabrication Equipment Market Analysis & Outlook Report 2024-2032@ https://www.snsinsider.com/checkout/7506

Table of Contents – Major Key Points

1. Introduction

2. Executive Summary

3. Research Methodology

4. Market Dynamics Impact Analysis

5. Statistical Insights and Trends Reporting

6. Competitive Landscape

7. Metal Fabrication Equipment Market by Equipment Type

8. Metal Fabrication Equipment Market by Material Type

9. Metal Fabrication Equipment Market by End User

10. Regional Analysis

11. Company Profiles

12. Use Cases and Best Practices

13. Conclusion

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.